|

We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website. |

CONTINUE |

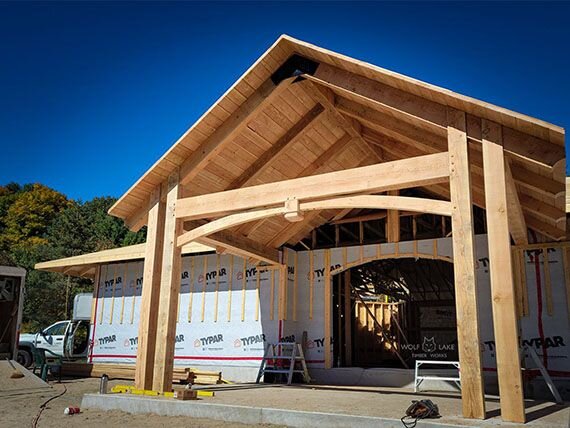

Our process is designed to make things easy, keep you informed, and ultimately deliver a timber frame that not only meets but exceeds your expectations. We can tailor designs to your specific vision, or you can choose from our high-quality designs.

This is where it all begins. Bring us your architectural plans or, if you’re still in the conceptual phase, anything that sparks inspiration – sketches, photos, or even a Pinterest board full of ideas.

We’ll sit down with you to learn more about your vision and ask the right questions: what’s the purpose of your structure? How do you see yourself (or your clients) using the space? What aesthetic are you aiming for – rustic charm, modern elegance, Muskoka-inspired warmth, or a combination?

Once we’ve defined the scope of your project, we’ll provide you with a detailed, itemized estimate. You can count on this estimate as a comprehensive breakdown of all associated costs – no surprises down the road. We’ll walk you through the line items and answer any questions you may have.

This is where your vision really starts to take shape. We translate our collaborative discussions and plans into a detailed 3D model, which allows you to see your timber frame from every angle and ensure that every detail is exactly as you imagine it. We’ll fine-tune this design as you wish until you’re completely satisfied.

Once you’ve approved the 3D model, we produce a full set of stamped, engineered shop drawings that meet all the relevant building codes and engineering requirements (including snow load) in your location.

With the engineered drawings as our guide, our master craftsmen begin the process of transforming raw #1 Douglas Fir timber into the components of your structure at our workshop just west of Peterborough, Ontario. Each piece of timber is carefully selected for its strength, beauty, and character, then cut, sanded, stained, and fit-tested by hand.

We use traditional mortise and tenon joinery, a time-tested technique that ensures exceptional strength and longevity, with no visible hardware. Every joint is fit-tested by hand, ensuring a perfect, seamless connection.

Your timber frame undergoes hundreds of inspections by our experienced craftsmen before it ever leaves our shop. It’s a fully hands-on process driven by a commitment to quality that's simply unmatched.

Your completed timber frame components are treated with the utmost care to ensure that they arrive safely on-site, ready for assembly. We handle the logistics, packaging each component carefully to protect it from the elements during transport, coordinating with your team to set up a timely arrival on your site.

If you have a skilled team or prefer a hands-on approach, you can assemble the structure with or without our guidance. Or, our experienced installation team can handle the entire process, from unloading to final assembly, for you.

No matter which option you choose, we're committed to making this final step as seamless and stress-free as possible.

This process, refined over years of experience, is why discerning homeowners, architects, and builders choose Wolf Lake Timber Works. It's the foundation of our commitment to quality, transparency, and lasting client relationships.

Discover the Wolf Lake Timber Works Difference